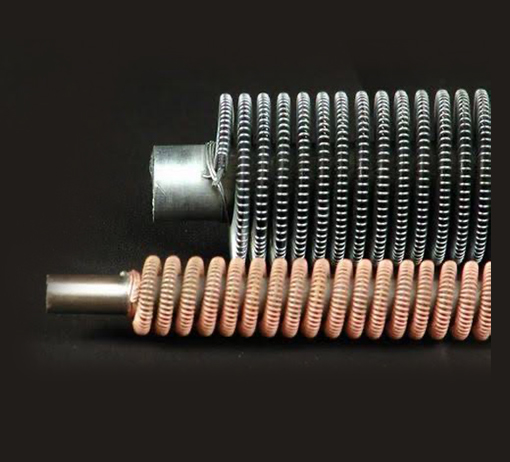

Fins are basically external surfaces on tube for increasing the surface area of the bare tube, resulting in a compact Heat Exchanger.

The method of attaching the fins over tube is of prime importance, since even a slightest air gap between the tube and fins will defeat the whole purpose of fins over the tube.

Considering the above facts Heft has indigenously designed and developed a special purpose tube fining machine capable of producing following types of finned tubes.

HEFT was formed in 1994 to provide the service to petrochemicals, power generation, chemicals, pharmaceuticals industries with high quality HELICAL WOUND FINNED HEAT EXCHANGERS tubing used in the maintenance and manufacture of the air cooled heat exchangers, air heaters & other related heat exchangers.

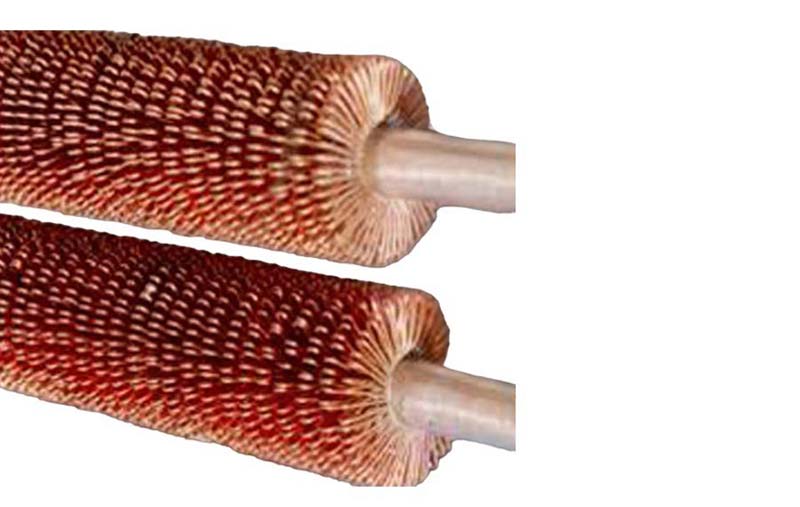

Finned tubes are able to even out the heat transfer between the inside of the tube and the outside. When the heat transfer coefficient on the outside of the tube is significantly lower than the heat transfer coefficient on the inside of the tube, there is a major advantage to incorporate fins on the outside tube surface to take full advantage of the high heat transfer rate on the inside of the tube.

By using a finned tube with eight times as much surface on the outside of the tube, the total length of the tube required for heating the viscous oil can be reduced by one sixth, Fins are basically external surface on tube for increasing the surface area of the bare tube, resulting in a compact heat exchanger.