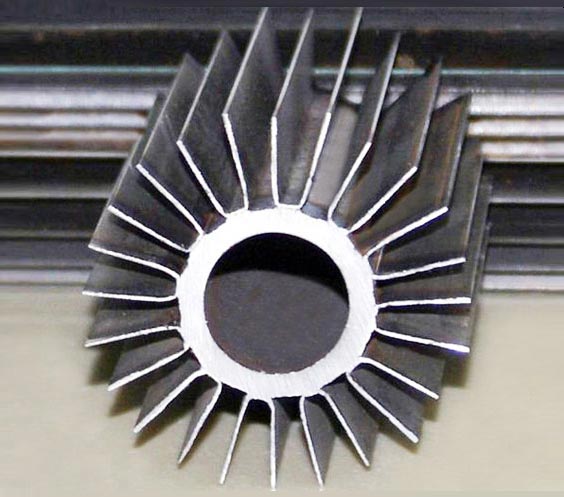

Longitudinal I/L or U-finned tubes are produced from resistance welded fins along the length of the tube. The fins first form a U-shaped channel so that each leg of the U forms a fin. Channels are cut to the appropriate length, then oriented and resistance welded in place along the length of the tube. The channels are welded in pairs, diametrically opposed, so the number of fins specified must be a multiple of 4.

Temperature range: Up to Maximum 415 Deg C

Manufacturing Capacity : 2,00,000 Meter Per Annum

Applications: This type widely finds acceptance where the requirement is for higher operating temperature and relatively lower corrosive atmosphere. Eg. Radiators, Air coolers in Power plants, Chemical plants

Features

• Increase heat transfer efficiency in effective space.

• Reduce the installation space of the required heat transfer surface

• Reduce equipment cost and have high operational reliability

• Reduce the pressure drop on the pipe side and reduce the operating cost.

• Provide 8 to 12 times the heat transfer area of bare tubes

Quality Control

• Inspection and Tests Performed

• Chemical Composition inspection

• Mechanical Properties Test(Tensile Strength, Yield Strength, Elongation, Flaring, Flattening, Hardness, Impact Test)

• Surface and Dimension Test

• Non-destructive Test

• Hydrostatic Test.

Applications:

Longitudinal fin construction is commonly used in shell and tube applications.

The choice of longitudinal finned tube versus helical finned tube seems to depend primarily on geometrical factors. For example, some heater structures consist of finned tubes inserted within other tubes - longitudinal finned tubes are the obvious choice for this type of application. In other cases, users prefer a longitudinal finned tube installation, where the tubes will be in a vertical orientation - the finned orientation facilitates fluid drainage on one side of the finned tubes.

Maximum temperature range: Above 600 deg C

Manufacturing capacity : 2,00,000 Meter per annum

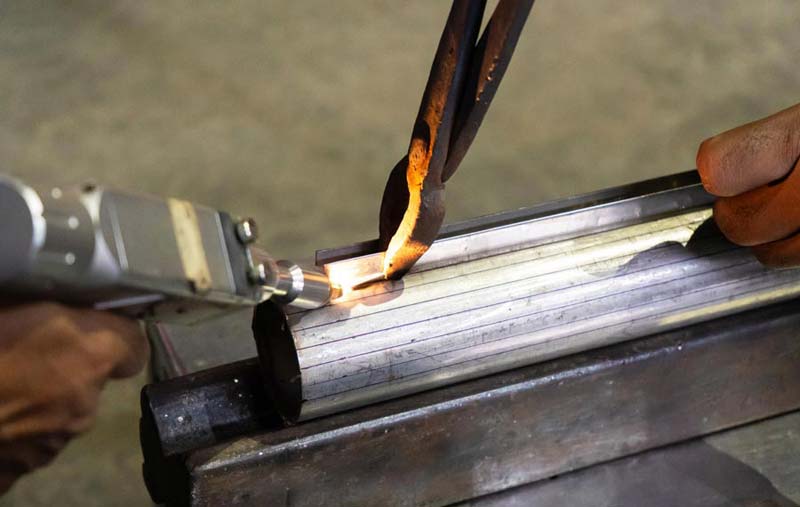

We have inhouse high frequency welding machine for longitudinal type built for high temperatures and large quantities of finned tubes.

Video Gallery

Step by step process for Longitudinal Finned Tube Manufacturing