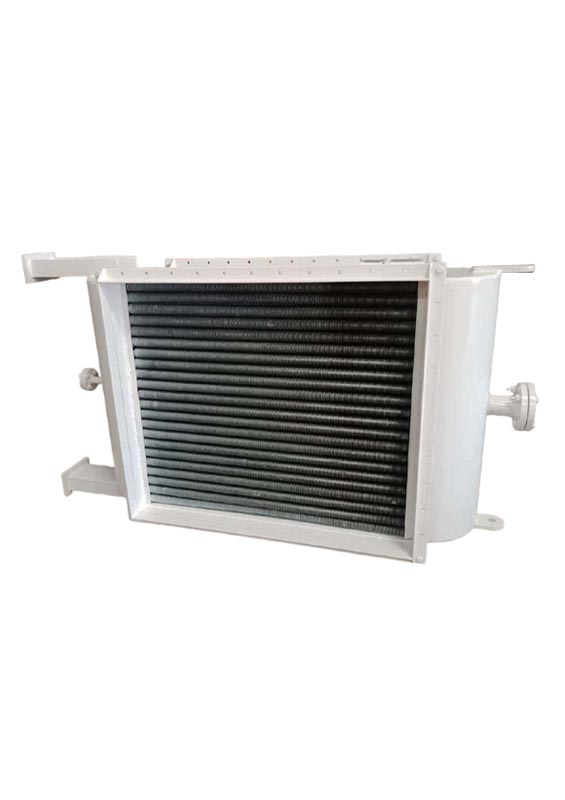

Air Heaters Manufacturer, Exporter, Supplier

Heft Engineers offers high-performance Air Heaters designed for efficient and reliable heating across industrial, commercial, and process applications. Our range includes electric, fuel-fired, steam, and duct heaters, engineered for optimal heat transfer, durability, and precise temperature control.

Suitable for drying, curing, HVAC, cleanrooms, and specialized environments, each unit is built to meet stringent quality and safety standards. With custom designs, energy-efficient solutions, and expert support. Heft Engineers delivers heating systems that perform consistently and reduce operational costs.

Air Heaters

Heft Engineers make Air Heaters are devices designed to heat air for industrial, commercial, and process applications, ensuring controlled and efficient thermal performance. They are available in various types, including electric, fuel-fired, steam, and duct heaters, each suited to specific requirements.

Electric Air Heaters provide clean, precise heating, while fuel-fired models deliver high-capacity performance for large spaces. Steam and hot water air heaters integrate seamlessly into central systems, and duct heaters are ideal for process lines and HVAC units. Applications include drying, curing, HVAC heating, cleanrooms, greenhouses, and moisture control.

Built for durability, efficiency, and safety, air heaters feature high thermal transfer rates, robust construction, and advanced control options, making them essential for consistent heating in demanding environments.

Key Features of Air Heaters

Air Heaters are designed to provide exceptional heating performance while combining durability, efficiency, and versatility, which makes them appropriate for a variety of commercial, industrial, and process applications. Even in challenging situations, their great thermal efficiency ensures quick and even heat transfer for a constant temperature output.

They can tolerate tough working conditions, high temperatures, and continuous operation because to their sturdy construction, which is made using premium materials and precision production. Thermostats, solid-state relays (SCR), and PLC-based systems are examples of advanced temperature control alternatives that enable precise adjustment for delicate processes.

These Air heaters come in a variety of forms, including electric, fuel-fired, steam, and hot water. They can be specially designed to meet particular airflow rates, temperature increase needs, and process conditions.

By minimizing hotspots and ensuring even heat distribution, their improved airflow architecture enhances process quality. They are simple to install, integrate, and maintain because of their small size and modular design. Reliable and secure operation is ensured by built-in safety features like airflow sensors, overheat cut-offs, and adherence to industrial safety regulations.

Air heaters are a reliable and sustainable heating option because of their energy- efficiency, which also lowers operating costs and lessens environmental effect.

Advantages of Air Heaters

➙ Fast & Efficient Heating : provides a quick temperature increase with little energy loss.

➙ Versatile Applications : are ideal for drying, moisture control, HVAC, and industrial operations.

➙ Customizable Designs : Tailored to airflow, temperature, and space constraints.

➙ Multiple Energy Sources : Available in electric, fuel-fired, steam, or hot water options.

➙ Consistent Performance : Ensures uniform air distribution for quality results.

➙ Durable & Long-Lasting : Built with robust materials for continuous operation.

➙ Easy Installation & Maintenance : Compact, modular designs reduce downtime.

➙ Enhanced Safety : Equipped with overheat protection, airflow monitoring, and safety compliance.

➙ Energy Savings : High efficiency reduces running costs and environmental impact.

Applications Industries of Air Heaters

➙ Food Processing

➙ Pharmaceuticals

➙ Chemical & Petrochemical

➙ Textiles

➙ HVAC Systems

➙ Automotive

➙ Plastic & Rubber

➙ Greenhouses & Agriculture

➙ Electronics & Semiconductor

➙ Power Plants & Utilities

➙ Printing Industry